The DMAIC toolkit is excellent for solving technical complexity problems. However, Lean Six Sigma tools are not as adept at...

- +65 61000 263

- Contact@COE-Partners.com

- Newsletter

The DMAIC toolkit is excellent for solving technical complexity problems. However, Lean Six Sigma tools are not as adept at...

Besides business and functional know-how, a successful leader must have competencies in leading change and improving, designing and managing processes....

Some time ago, I was facilitating a Six Sigma project group involved in solving a process challenge. This group had...

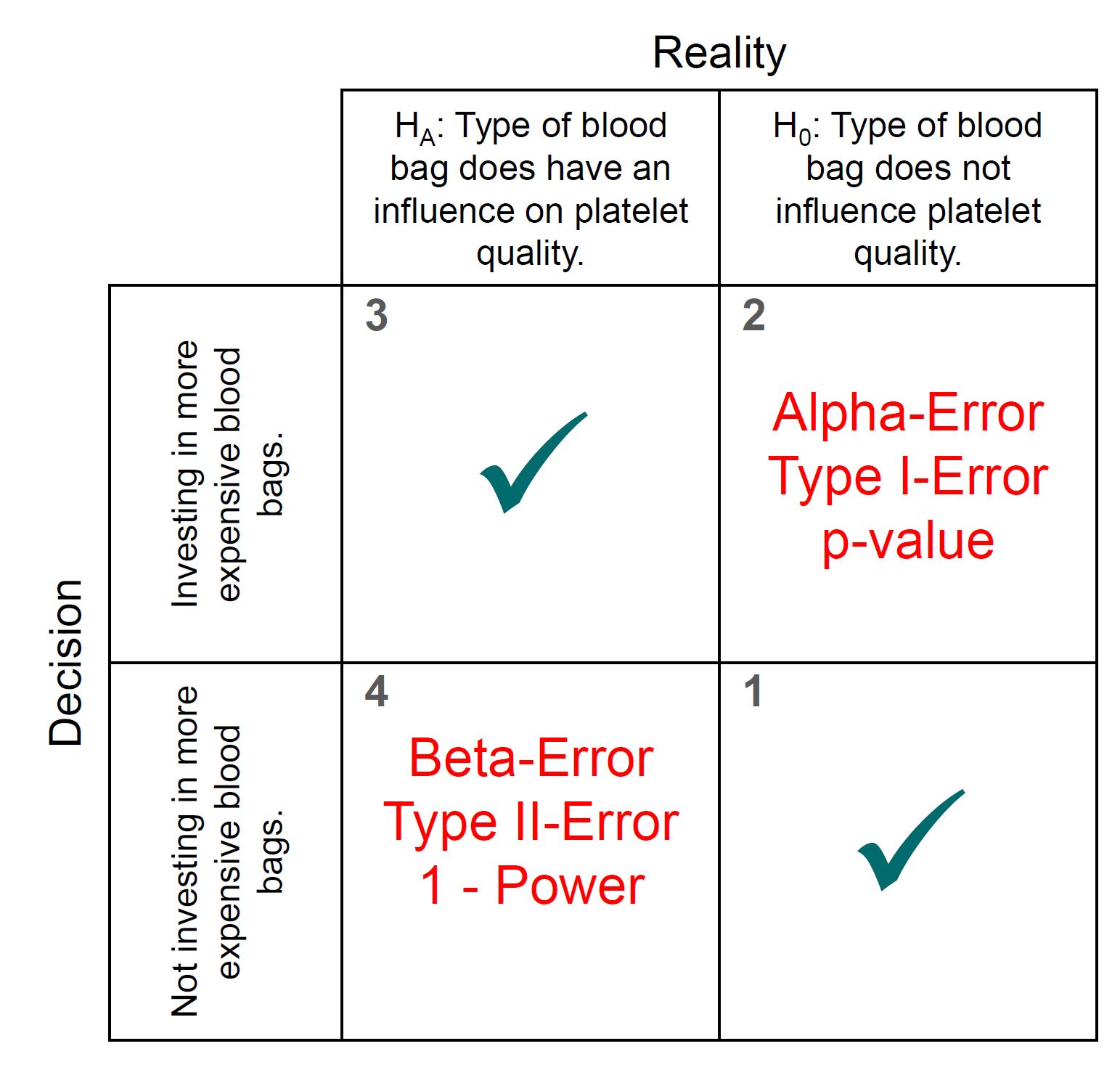

Rejecting a null hypothesis when it is false is what every good hypothesis test should do. The “power of the...

New undertakings or experiences are always challenging at first. This is no different when Schenker Singapore (Pte) Ltd, a transportation...

Everyone, undoubtedly, has had the unenviable honour of experiencing ‘bureaucratic government processes.’ Be it applying for your first ID or...

Six Sigma has been developed decades ago and fine-tuned by many companies since then. However, there is no ISO standard...

The job of purchasing is obviously to source for reliable suppliers who deliver products conforming to specification on time within...

“Don’t use Six Sigma to tackle special cause variation!” is one of the common phrases being repeated by Lean Six...

Against the common belief, statistical knowledge is not a criterion for selecting your Belts. However, the capability to acquire new...

A couple of years ago, I was meeting the President of an Asian multi-national mid-sized service company for a Six...

Some well-known companies have been “doing Six Sigma” for years. They keep doing improvement projects in all kinds of business...

Globalisation and instant access to information, products and services continue to change the way our customers conduct business. Today's competitive...

Background OurBank is an American international bank with 50 branches in Germany and approximately 300 employees working either in the...

Copyright © 2025 by COE Pte Ltd. All Rights Reserved.