Two weeks after joining Central Bank in Germany, I spend a full week in the so-called Black Belt Training by...

- +65 61000 263

- Contact@COE-Partners.com

- Newsletter

Two weeks after joining Central Bank in Germany, I spend a full week in the so-called Black Belt Training by...

Becoming a Black Belt is not for everyone. More important than statistical knowledge are personal traits and some leadership characteristics....

Every year around December, he gets very busy. He plans for the big event and he wants to make sure...

Discussing workforce planning with an HR professional of a government entity in Singapore we explained our approach that starts from...

Imagine you join a new kind of job in a different line of business you don’t have any experience in....

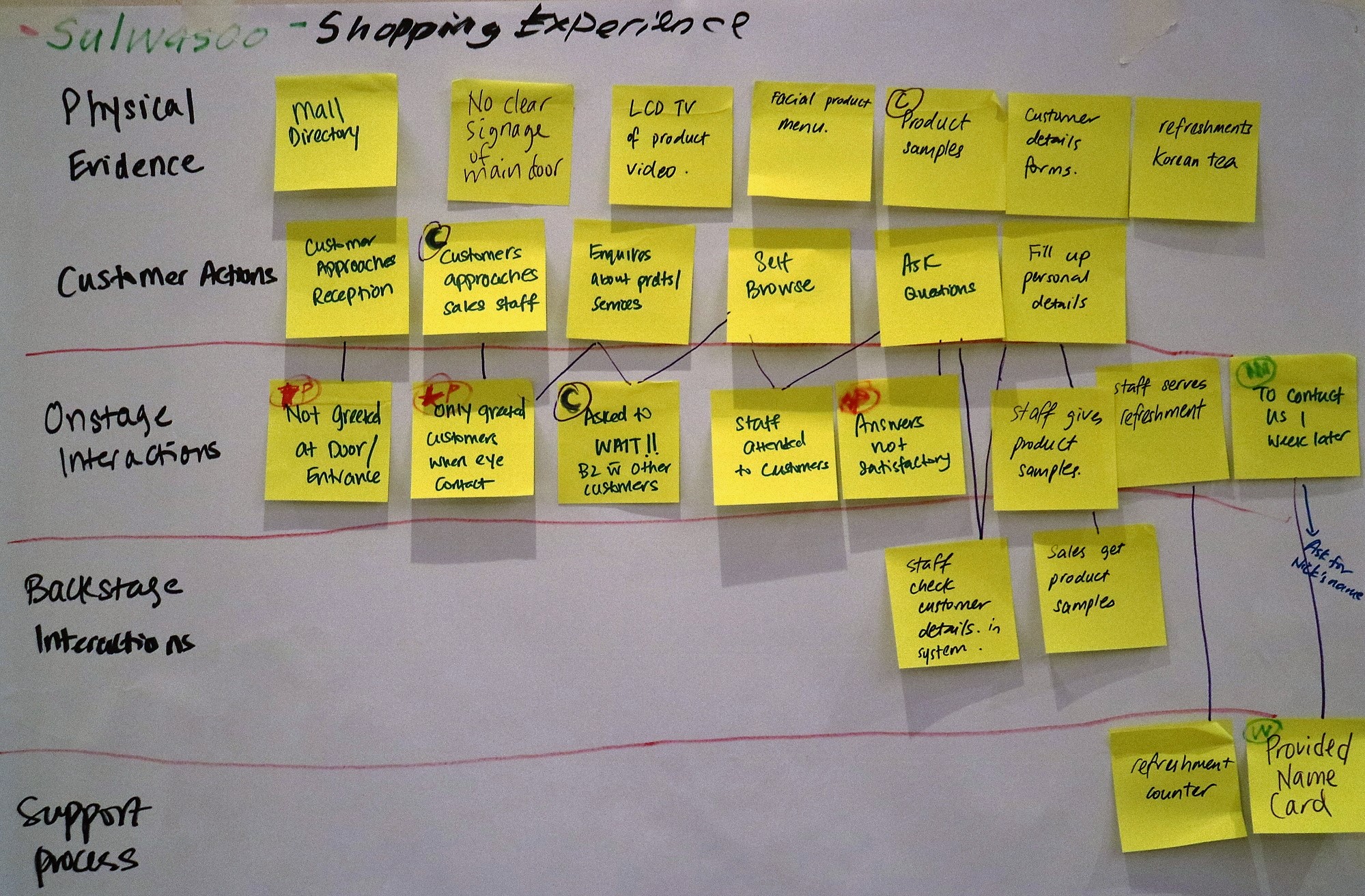

Especially in service organisations, productivity is usually quite low due to a lack of efficiency caused by a missing focus...

“We need to increase productivity!” What sounds very reasonable on a country scale could be damaging on a company level....

To find the most valuable Six Sigma projects – ones with the highest system-level leverage – can require systems thinking...

Besides business and functional know-how, a successful leader must have competencies in leading change and improving, designing and managing processes....

New undertakings or experiences are always challenging at first. This is no different when Schenker Singapore (Pte) Ltd, a transportation...

A typical Friday evening starts with a family dinner in a nice atmosphere. This time we decide to visit one...

A couple of months ago, I was having lunch with the Chairman of a medium-sized contract manufacturing company in Singapore....

Everyone, undoubtedly, has had the unenviable honour of experiencing ‘bureaucratic government processes.’ Be it applying for your first ID or...

Six Sigma has been developed decades ago and fine-tuned by many companies since then. However, there is no ISO standard...

The job of purchasing is obviously to source for reliable suppliers who deliver products conforming to specification on time within...

Copyright © 2025 by COE Pte Ltd. All Rights Reserved.