Continuous improvement does not start with massive Lean Six Sigma or Innovation initiatives. Continuous improvement needs to be part of...

Continuous improvement does not start with massive Lean Six Sigma or Innovation initiatives. Continuous improvement needs to be part of...

No one delivers defective parts, wrong information or even typos in emails intentionally. It is usually our processes that allow...

You will know when Six Sigma is finally part of your organisation’s bloodstream because it will no longer be necessary...

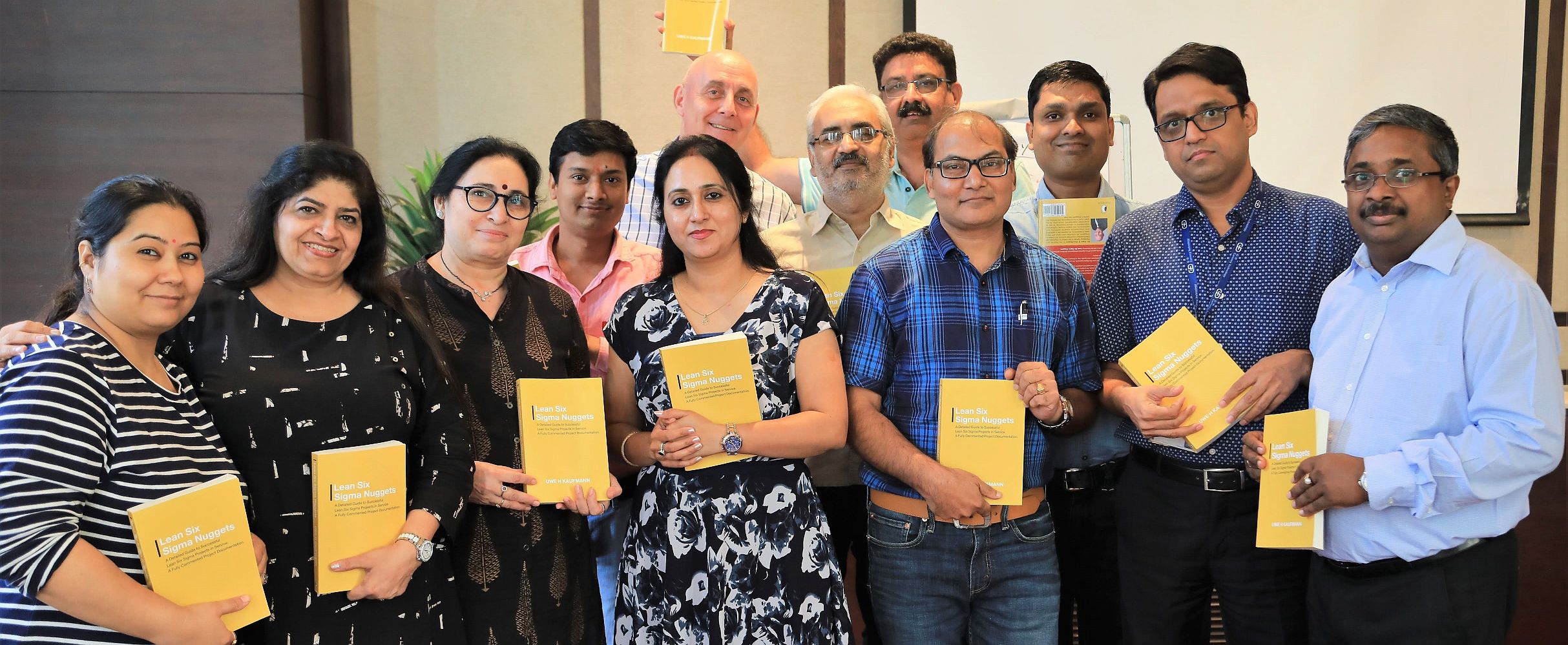

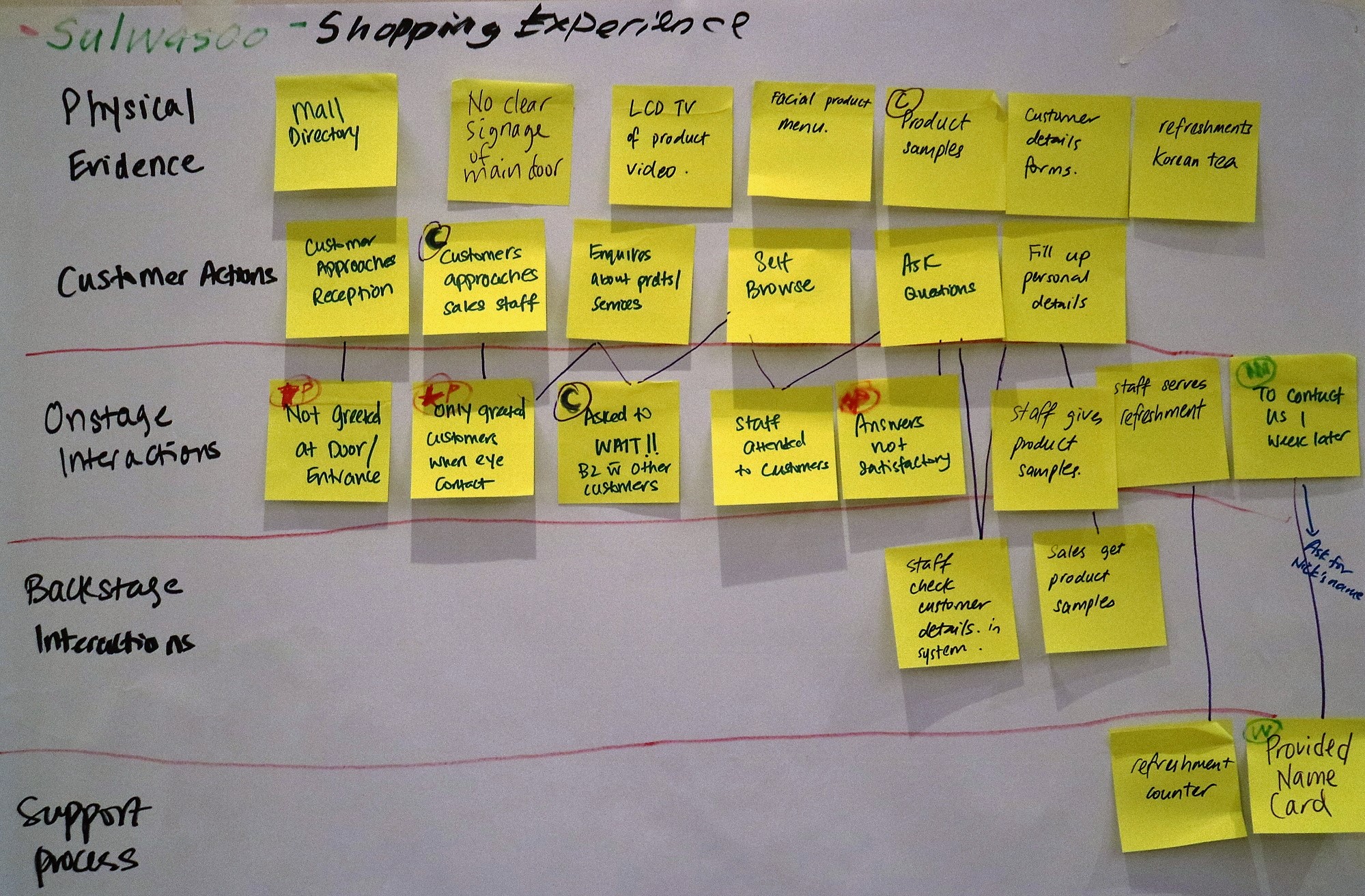

Lean application outside of the manufacturing sector is frequently met with scepticism. Oft cited reasons are that service providers do...

In response to evolving conditions, you came to realise that your organisation must change. Change leadership consists of project sponsor,...

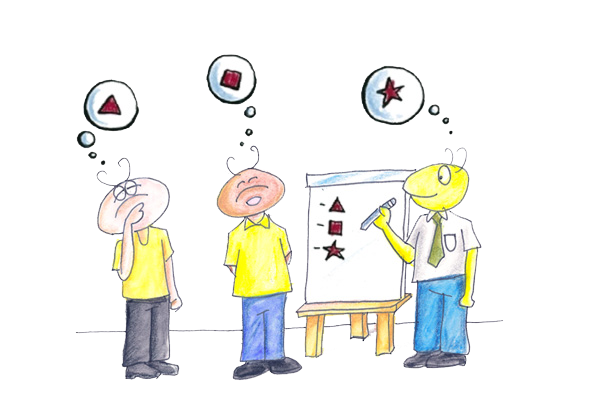

Ting is a sophisticated traditional Chinese character that exemplifies the most important activity related to customer service in an impressive...

Here are some typical Questions and our Answers regarding the deployment of Lean Six Sigma in an organisation. If you...

Not every organisation needs to develop process managers with Lean and Six Sigma skills. Yet, every organisation deserves to have...

Two weeks after joining Central Bank in Germany, I spend a full week in the so-called Black Belt Training by...

Becoming a Black Belt is not for everyone. More important than statistical knowledge are personal traits and some leadership characteristics....

I was chatting with a friend of mine who is in a senior leadership position. He wanted to implement a...

Especially in service organisations, productivity is usually quite low due to a lack of efficiency caused by a missing focus...

“We need to increase productivity!” What sounds very reasonable on a country scale could be damaging on a company level....

To find the most valuable Six Sigma projects – ones with the highest system-level leverage – can require systems thinking...

Increase in productivity can be achieved in multiple ways. The myth of implementing IT support as cure-all for productivity problems...

Copyright © 2026 by COE Pte Ltd. All Rights Reserved.