Robotic Process Automation (RPA) is one of the newer concepts for making our business and personal life easier. And this is not that difficult to implement.

Why Should We Partner With Robots?

Business processes have a great potential for RPA, if they are repetitive, rule-based, time consuming and still run by humans. This includes activities that are performed in the same way very frequently like

- requesting and collecting data for report compilation,

- data transfers to other business units, clients, suppliers or government agencies,

- processing large data operations like payroll, accounts payable, accounts receivable,

- handling of online orders for ecommerce businesses,

- onboarding, offboarding, leave and benefits calculation and processing and many more.

Certainly, humans doing such work are easily disinterested and fatigued. Sooner or later, this leads to mistakes.

RPA – A New Name for an Old Concept

Although the name Robotic Process Automation (RPA) seems still new to many, the concept itself is not. Many of us have RPA-like solutions sitting on our computers without calling it that way. To put it simply: RPA is software. Software robots.

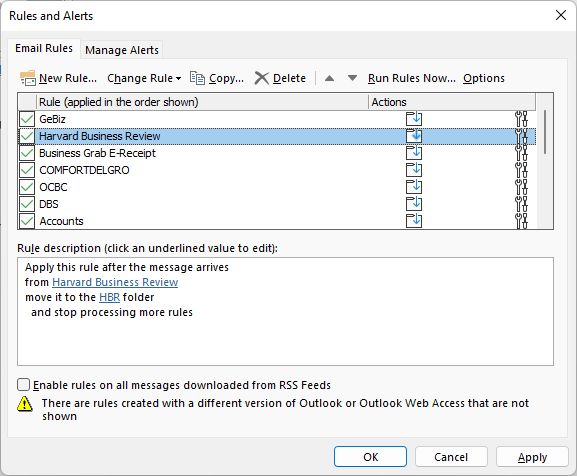

For example, we have rules working in the email system to auto respond to certain messages from defined senders or with certain text in subject or body or just to let everyone know that we are on vacation.

Other rules take care of mundane tasks like saving certain messages in predefined folders and making them read. These are messages we do not want to lose but we do not find critical enough to open immediately – important but not urgent messages. We open them when we need them.

These rules save time and help automating repeating tasks that otherwise would have been done manually by humans the same way every day. Now we call this kind of solution RPA. RPA is a form of process automation where software robots mimic humans doing routine tasks without human intervention with higher speed and greater accuracy, that is, free from human errors.

A great advantage of RPA is its simplicity because it does not need any programming skills to define rules for the email system or recording macros in MS Excel.

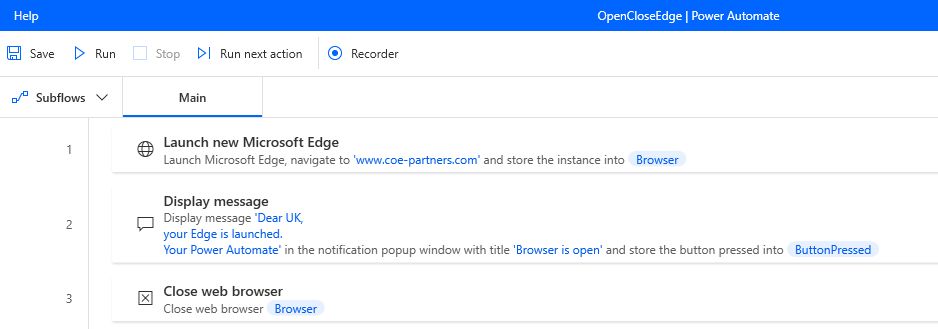

This applies to many other RPA software solutions similarly, that can be implemented with ease by office workers on their desktop, their mobile phones, on servers or in the cloud.

As a result, with minimal training, nearly everyone can program and execute the available RPA tools to make their life easier, be it in the office or at home.

RPA is Easy – Do You Really Need It?

However, this simplicity comes with a drawback. Because if it is much easier to leave boring human tasks to a software robot to do, it is tempting to ignore the ever-important question “Is there a better way of doing our work?”

Before Automating Your Organisation’s Processes,

Find Ways to Improve Them!

Studying processes in all kinds of public and private organisations, one finding is ubiquitous. We spend a significant amount of our working hours on activities we call non-value-added. Non-value-added means that the process customer does not really care whether this is being done or not.

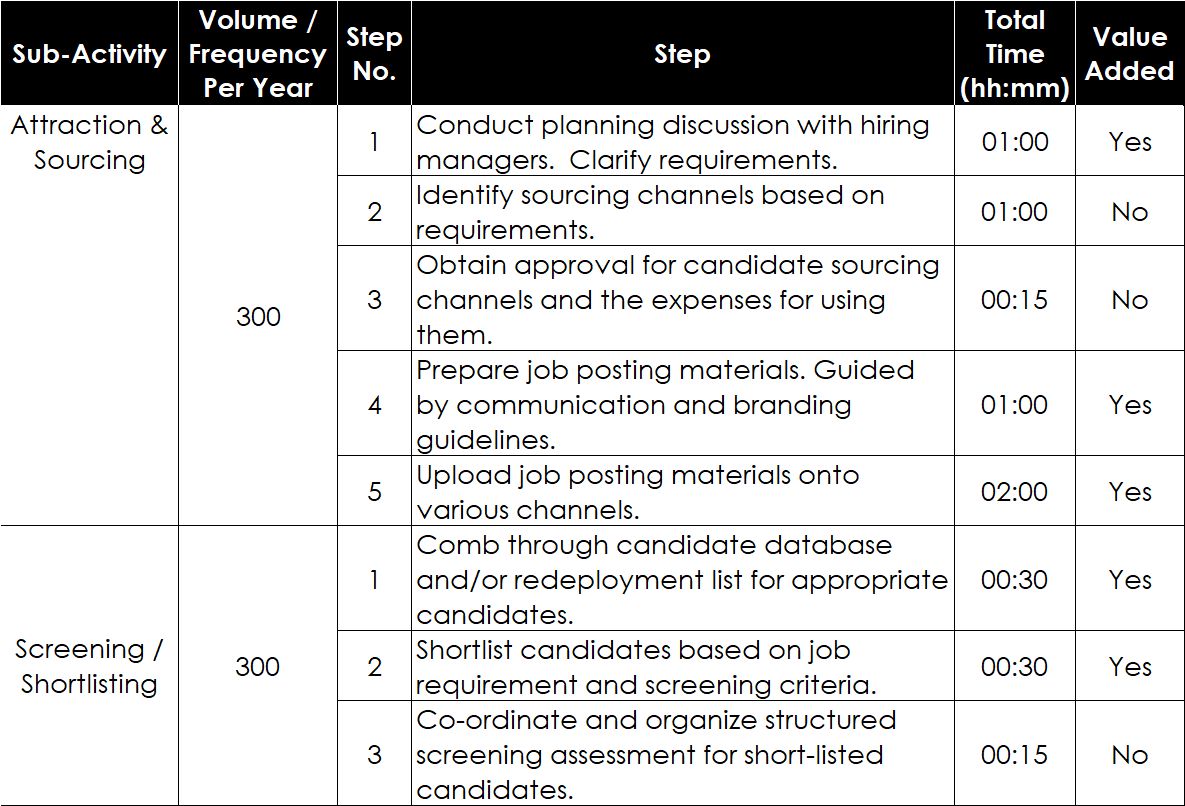

Let’s take an example: Assuming an organisation hires about 300 people per year. As shown, certain activities of this Talent Acquisition and Resourcing process need to be repeated 300 times.

This process map reveals that step 3 at Attraction & Sourcing, Obtain approval for candidate sourcing and expenses is also done 300 times and rightly considered non-value-added.

During the process study, staff involved into this Attraction and Sourcing activities highlighted some room for partially automating the steps of forwarding and tracking requests for approval to the deputy director 300 times. RPA could certainly help.

However, if the team and the deputy director would put their heads together a few times a year – instead of 300 times – and plan for sourcing channels and budget, the process would not only use less of our resources for repeating tasks but speed up as well.

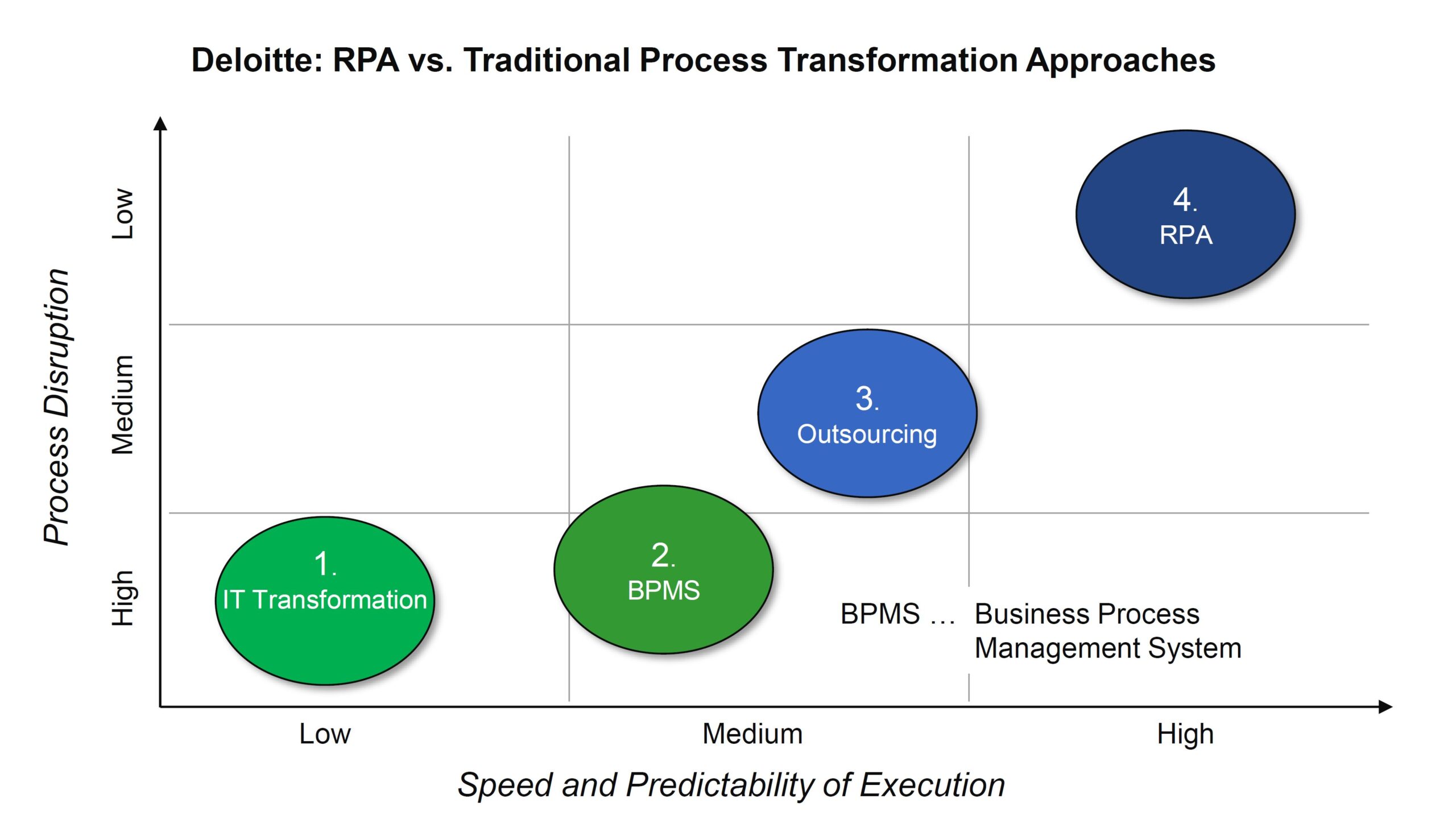

For this and many other activities, process improvement or reengineering should be done before considering Robotic Process Automation (RPA). Michael Hammer once quipped “Automating a mess yields an automated mess!”

The answer on the above question is: Yes, you most likely need RPA. Yet, not for all processes you may have in mind.

RPA Needs Change Management

Robots are faster and cheaper than human workers doing the same job. Moreover, they work virtually error-free. And, the risk that robots will talk to the union is quite slim. As a result, all these characteristics make RPA a very scary perspective for those workers and a dream for the management.

Therefore, it is essential that RPA does not come as a surprise for the operators but is introduced carefully. After all, if the software robot is supposed to mimic the human activities, these activities need to be mapped and understood first.

Chances are that the process operators even have ideas for improving the process before entrusting it to the software.

Yet, they will only help with the former and the latter, if they realise that they do not jeopardise their own existence.

So, this requires a change management plan that does not only take care of the change of the process but, more importantly, of the change for the people. These prople will appreciate when they undergo some job redesign after someone talked to them about their career opportunities.

They just want to know that management cares for them as well, not just for the sexy new tools.

Conclusion

The main difference between Robotic Process Automation, called RPA, and other automation solutions is its ability to mimic human interaction with the help of IT systems. The following advantages seem obvious:

- RPA is cheaper than humans doing the same work. A software robot costs much less than one FTE (full-time-equivalent employee) and can perform the job of multiple FTE.

- RPA can execute repeating activities much faster than humans. Humans are taken out of this part of the process.

- This makes RPA working virtually error-free. This only applies if process owner and stakeholder have successfully transferred the job to the RPA software. This must include all variants of the process.

RPA does not redesign processes nor does it ask whether there is room for improvement. Hence, if we pass a dysfunctional process to the RPA software, it will just run it that way.

Preparing a process for RPA involves studying it regarding its steps and the polices governing them. This seems to be a superb opportunity for applying Lean Six Sigma or Lean Innovation before letting the software run it.

Finally, do not forget to manage the change!