Your Lean Six Sigma initiative has taken off well, project teams led by Belts have done a nice work and results are in. Good job so far?! However, this is the rather easy part of your journey. The more difficult part is about retaining and accelerating the trained Black Belts and Green Belts (Belts).

General Electric’s Management Development Programme includes a compulsory module about Lean Six Sigma. Without having a “Belt” no one has a chance to be promoted into the upper management in GE.

Excellence in Talent Management

Step 1: Begin with the End in Mind – Your Current and Future Business Needs

We need a robust and systematic tool to select and train future leaders for our company. What I’ve read about Six Sigma so far was about focusing on customer requirements, managing and improving processes, changing the company’s culture, encouraging people and, last but not least, making money. This is exactly the job of our leaders. Therefore, we want to use Lean Six Sigma as part of the management development programme to select and develop the next generation of leaders, the president of an Asian multi-national company responded when asked why he wanted to kick-off Lean Six Sigma[ii].

We are a government regulatory agency. There have been consistently unpleasant feedback and complaints in newspapers by our customers about our service and process turn-around time. Who will be suitable to bring up our customers’ experience by optimising our processes?, was the explanation of a director in a government agency on the question what they want to use Lean Six Sigma for.

Step 2: Selecting Belts – What Kind of Talent Does The Business Need?

- Personal Interest in the programme is one of the most important factors. It is much easier to teach methodology and tools to people with the right mindset than making a disbeliever (typically low interest) a Lean Six Sigma evangelist.

- Organisational Knowledge And Business Acumen provide focus for individual’s energy and drive key business initiatives & priorities that will expand business, increase market share or improve profitability.

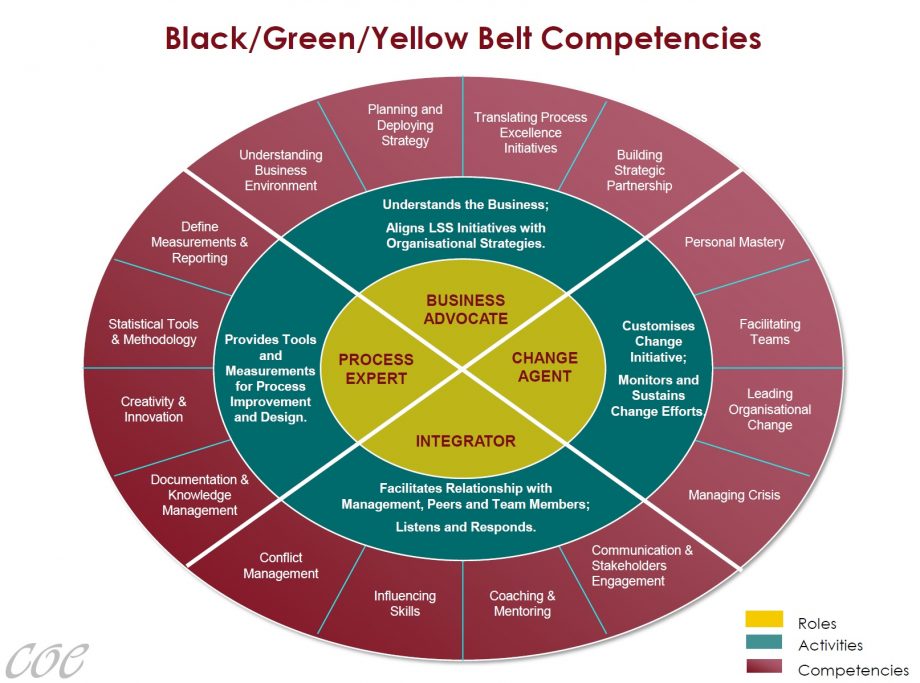

- Competencies are the broad challenge to which the Belts must step up, to drive successful execution of the strategic priorities (e.g. driving change, generating ideas, controlling costs, developing others, etc).

- Personal Attributes – such as customer orientation, be it external or internal customers – is essential for succeeding in Lean Six Sigma and a major step from process improvement towards customer satisfaction. Self motivation and risk taking are other key personal attributes to ensure success in this role. People management skills comprise of a list of key strengths that are fundamentals to win.

Step 3: Developing the Potential of Belts

Many common mistakes companies have made at developing the Belts include:

- Selection without subsequent diagnosis of additional development needs

- Focus on current performance alone

- Inconsistent assessment criteria

- Only focus on strengths (no consideration of leadership potential derailleurs)

a) Evaluating Current Performance

b) Identifying Leadership Potential

- taking best advantage of and

- responding positively to differential development opportunities,

- supporting the organisation’s values, as well as

- being able to apply what is learned productively within the organisation.

c) Creating Opportunities For Acceleration

Step 4: Assessing the Readiness of Belts for Leadership Transitions

a) Individual Readiness

COE’s approach to assessment using 360 Degree Survey (360ELP) complement with coaching/mentoring, focus on others’ perceptions of performance in a current role is a powerful diagnostic for development.

b) Organisational Readiness or “Talent Pulse-Rate”

Step 5: Developing and Driving Performance

In any context, though you need rigor in how development is executed. Effective development requires a blend of activities including mentoring, classroom learning, coaching, action learning, etc.