Do You Like Spaghetti?

About unnecessary motion and other lean sins

“I did a lot of spaghetti walk this morning”, was uttered by my wife after we left our house. “What did you cover with your spaghettis?” was my question knowing that she was talking about her usual very complicated process of getting ready for a client visit.

She explained “After I thought I was done in the bathroom standing in the wardrobe I recognised that I needed a hairclip from the bathroom that matches my dress. Back in the bathroom, looking at my hairclips, I saw one I have not worn for a while. I wanted to give it some fresh air. After taking my beloved hairclip and going back into the wardrobe, I found that the dress that goes with this hairclip because of an outstanding colour-match looked a bit aged.”

She went on “I decided to drop the dress idea and zoomed in on a nice suit. This suit needs a different hair style and hairband. For that I had to go back to my bathroom and bedroom to pick them up.”

And then “When I was trying to put on my shoes in front of the shoe rack being already fully dressed, I mysteriously did not find those that go with this suit.

Back in the wardrobe, I could not locate them either. Hence, I needed to wear other shoes that require a different dress, another pair of stockings and some other accessories.

And that was only the spaghetti walk for getting dressed”, was her conclusion. And, I have the strong feeling that this is similar every day.

About Adding Value

from the Lean perspective

If this kind of thing happens at home, it only makes the husband wrinkle his forehead. If this happens in a business, it is called non-value-added steps and waste – although my wife would never agree to this statement at home.

Following Lean, value-added steps are characterised by three criteria

- The customer requires this step to be done.

- The step causes an expected physical change.

- The step is done right the first time.

I dare to call myself customer in the process described above and agree that I want her to look good. Ticked.

These steps certainly cause a change of outfit. Although, she does look stunning even in pyjamas, I prefer her to dress up. Ticked.

The last criteria kills most of her steps as non value-added. Value added would be doing it once – like me. I select a black shirt out of about 20 black shirts, a black pants out of about 10 black pants and black shoes. This is what I call a highly efficient process. Each step adds value, hence my efficiency is towards 100% – if I don’t need to tie my laces twice.

Spaghetti Walk in Your Organisation

Beware, it comes in the dress of daily activities

A bit of spaghetti walk at home is no big issue. In your business however, spaghetti walk or other steps that are not really needed have the power to drain significant resources, burn out your staff and turn customers away.

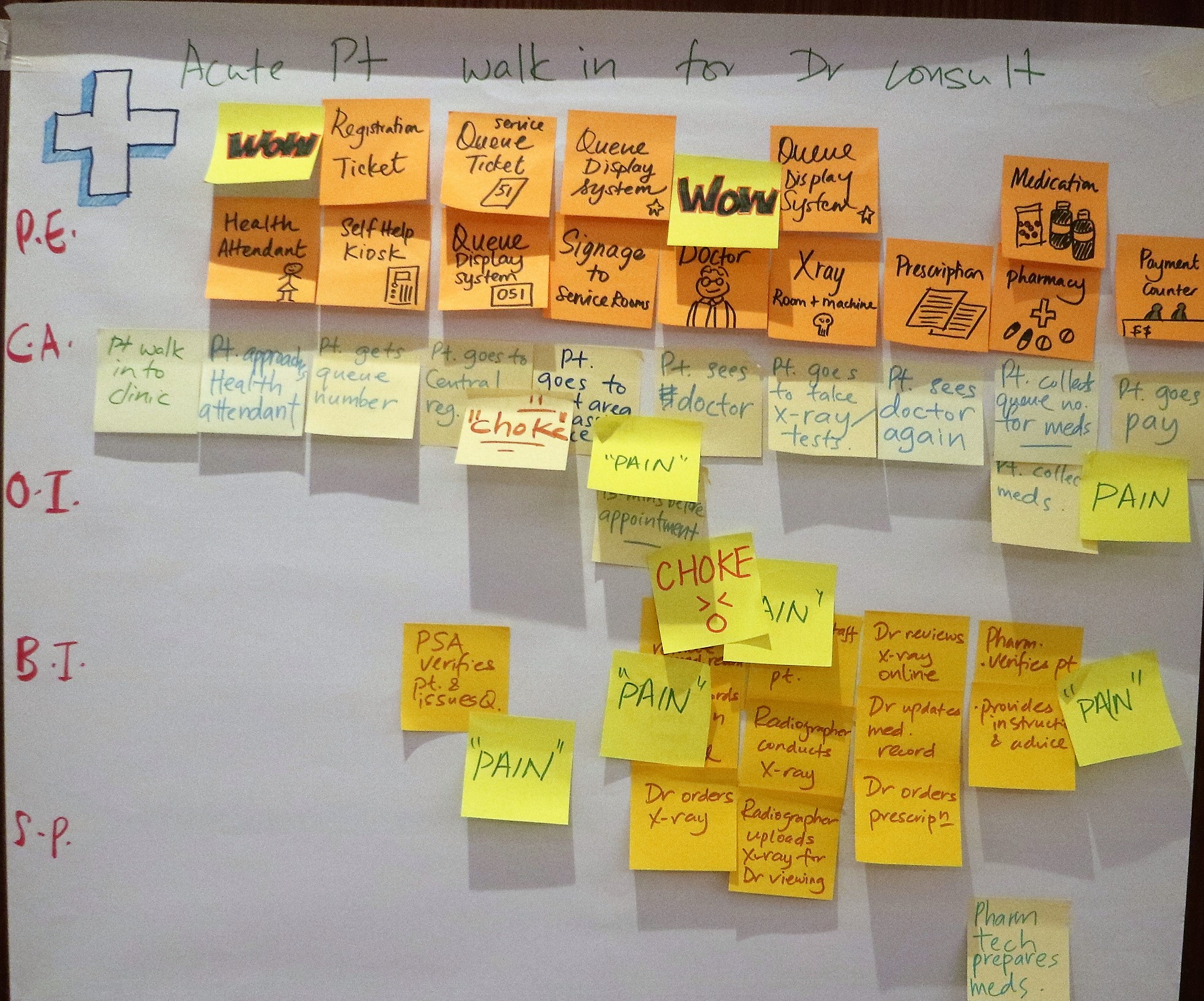

For example, when the customer calls and you cannot answer whether the requested items are on stock because the warehouse management system does not talk to the frontline system often enough, multiple internal calls might be necessary whilst the customer is still on the line.

Your customer gets impatient and frustrated quite fast and with him your staff. Both will be on the lookout very soon.

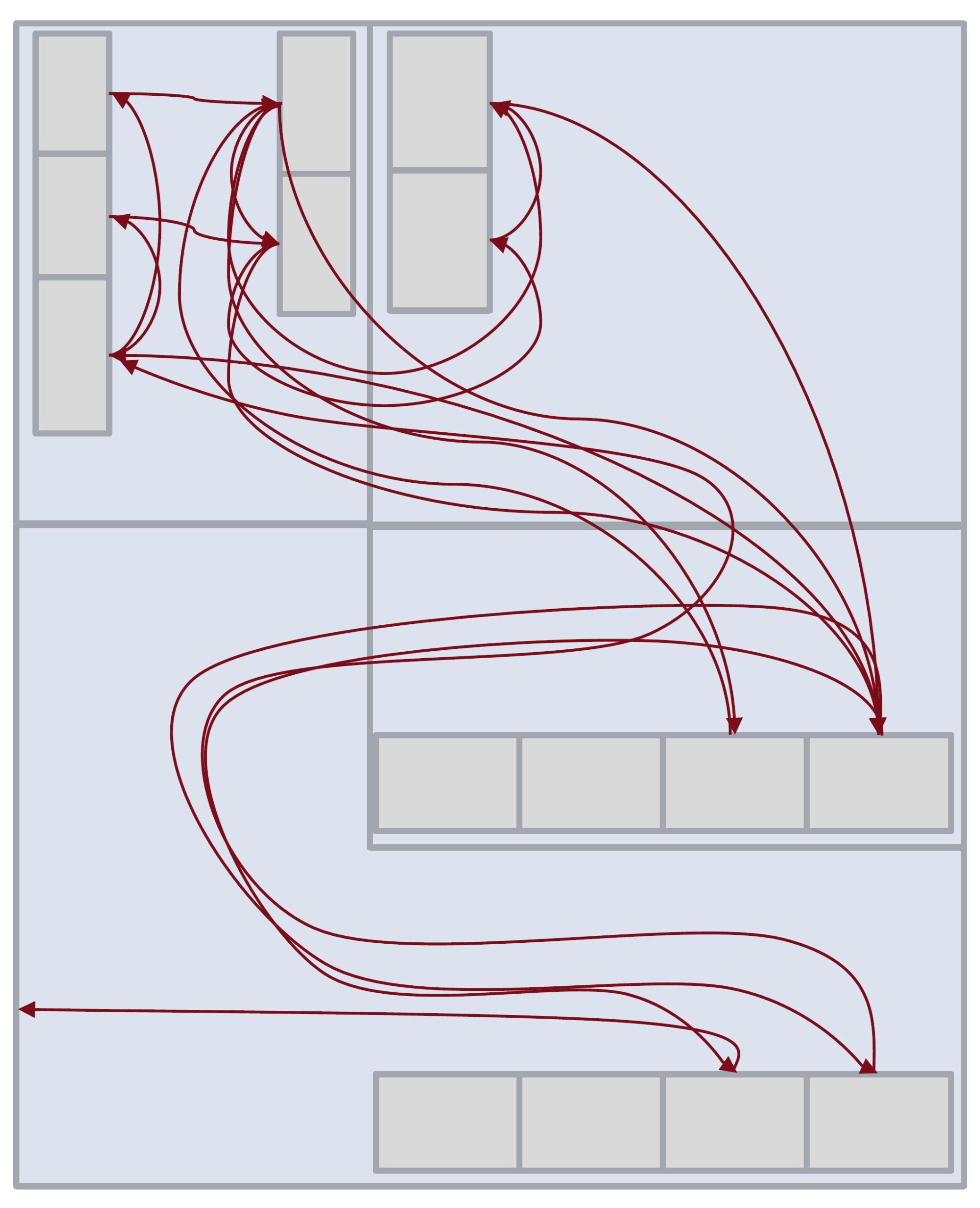

Spaghetti walk is also a fair judgement for the following observation: Living in the East and going to the West to pick up the company car from office in the morning before you go back to the East to perform your car-bound duties and doing the whole exercise in reverse in the evening burns about 30 to 40% of the working hours. Of course, this exceptional waste needs to be compensated by extra workforce. This makes this spaghetti walk very expensive.

And, only few staff members would not recognise that what they do does not make sense.

The Problem with Non-Value-Added Activities

and their consequences

These non-value-added steps lead to low process efficiency, i.e. only a small portion of the time spent on processes really adds value. Whilst some manufacturing organisations proud themselves with high productivity, in the service sector it is traditionally low.

The biggest room in the world is the room for improvement.

Helmut Schmidt, German Chancellor

Part of this gap can be explained with the proximity of service businesses to their customers. The bank, for example, spends a large portion of the processing time with customers either face-to-face, on the phone or on email with all the variation added by different customer requests. In a Volkswagen plant to the contrary, customers do not disturb the assembly line, but buy the final product at the end of the process.

Yet, this is a cheap excuse for messy processes, and there is still lots of potential for innovative improvement in service to avoid squandering precious resources under the headline of “serving the customer”. Why would you pay staff when getting only a small portion of value-added work in return? And, this is not their fault.

Reducing the Spaghetti Walk

and other non-value-added activities

So, what can we do about that?

Since this problem is in no way new, there have been studies to deal with it resulting in strategies that are applied in many industries. Especially in smaller organisations the problem lies in recognising the issue.

The good news is, that it might be easier for you to start the change than for me asking my wife to alter her life-long habits of getting dressed. After all, my case for change is quite weak.

If you define the problem correctly, you almost have the solution.

Steve Jobs, Founder of Apple

When you “walk your processes“, be it physical or those on phone, email or IT system, do you recognise your plate of spaghettis the same way my wife did?

If not, you are not alone. This needs a certain mindset, a Lean mindset. Start building it and you will see results.