19 Nov 2025

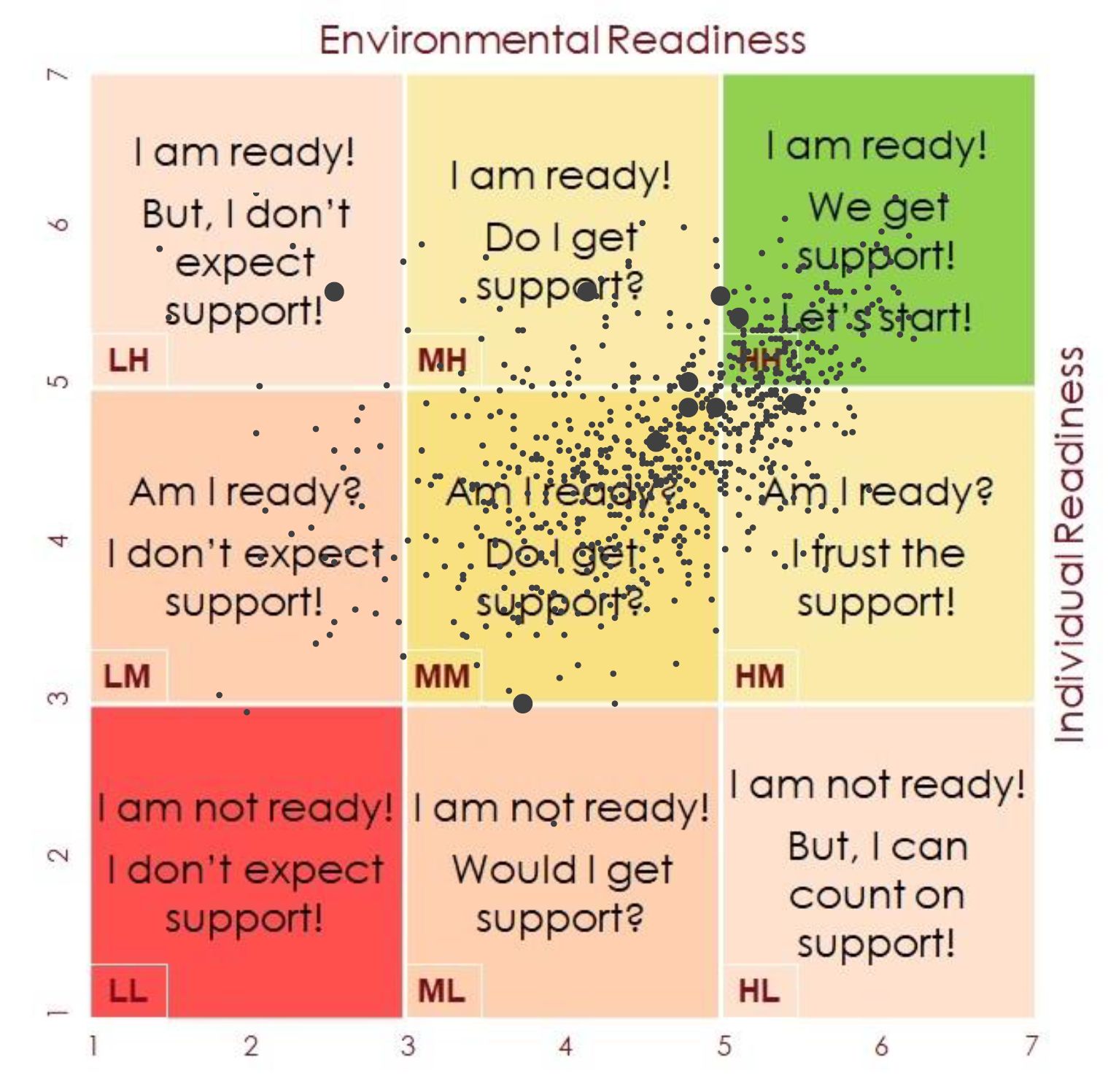

Feeling the Pulse of your Organisation.

Identifying Issues. Motivating Participants.

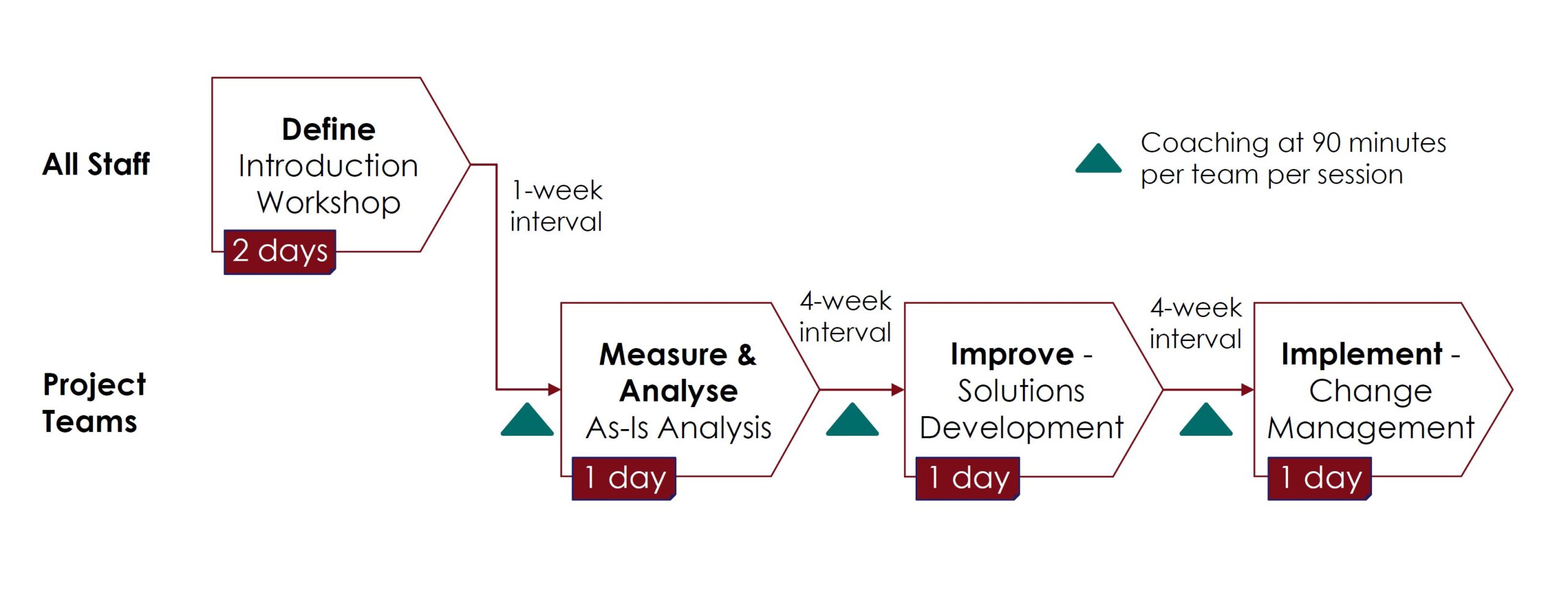

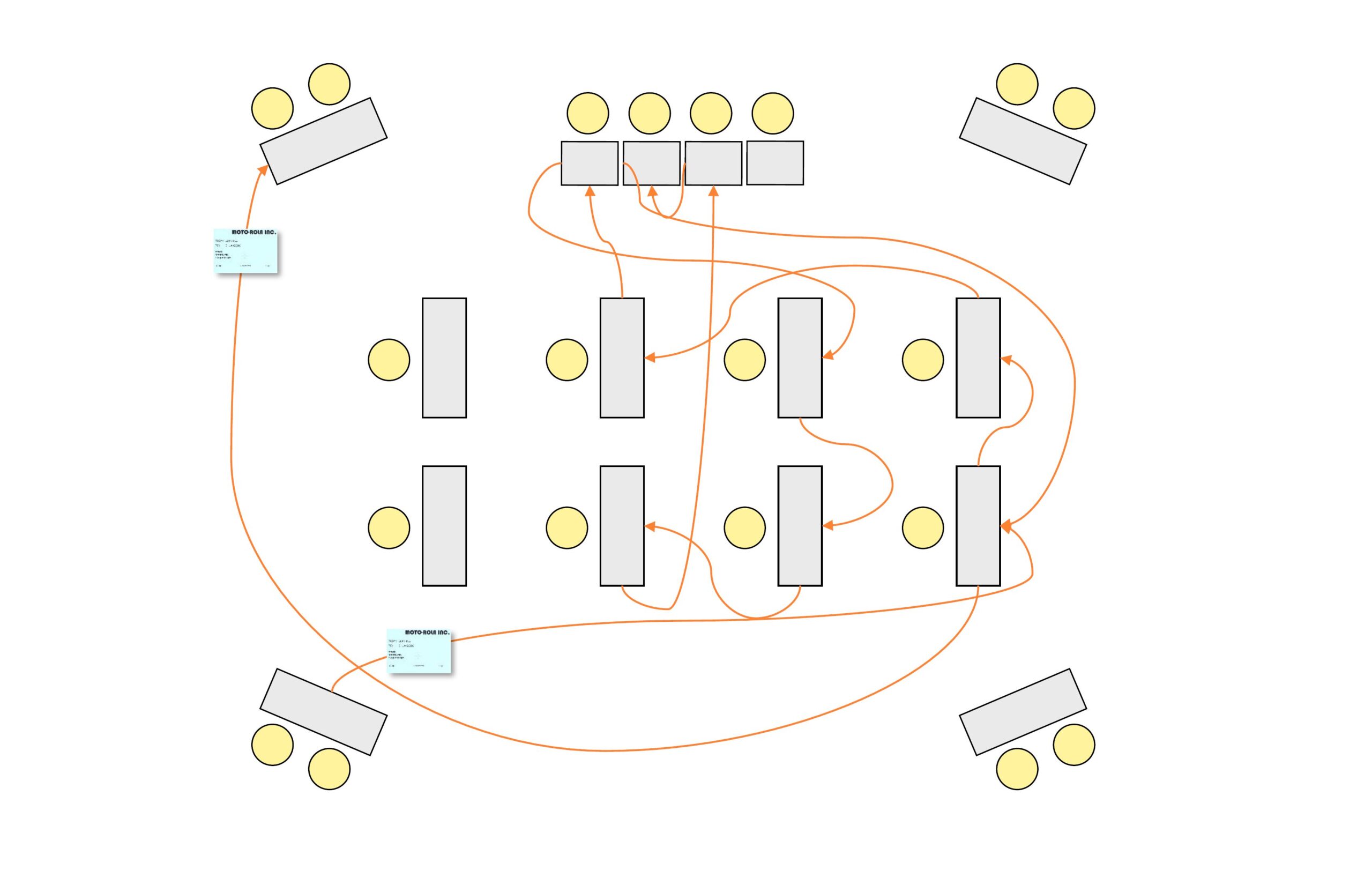

Understanding Issues and Root Causes.

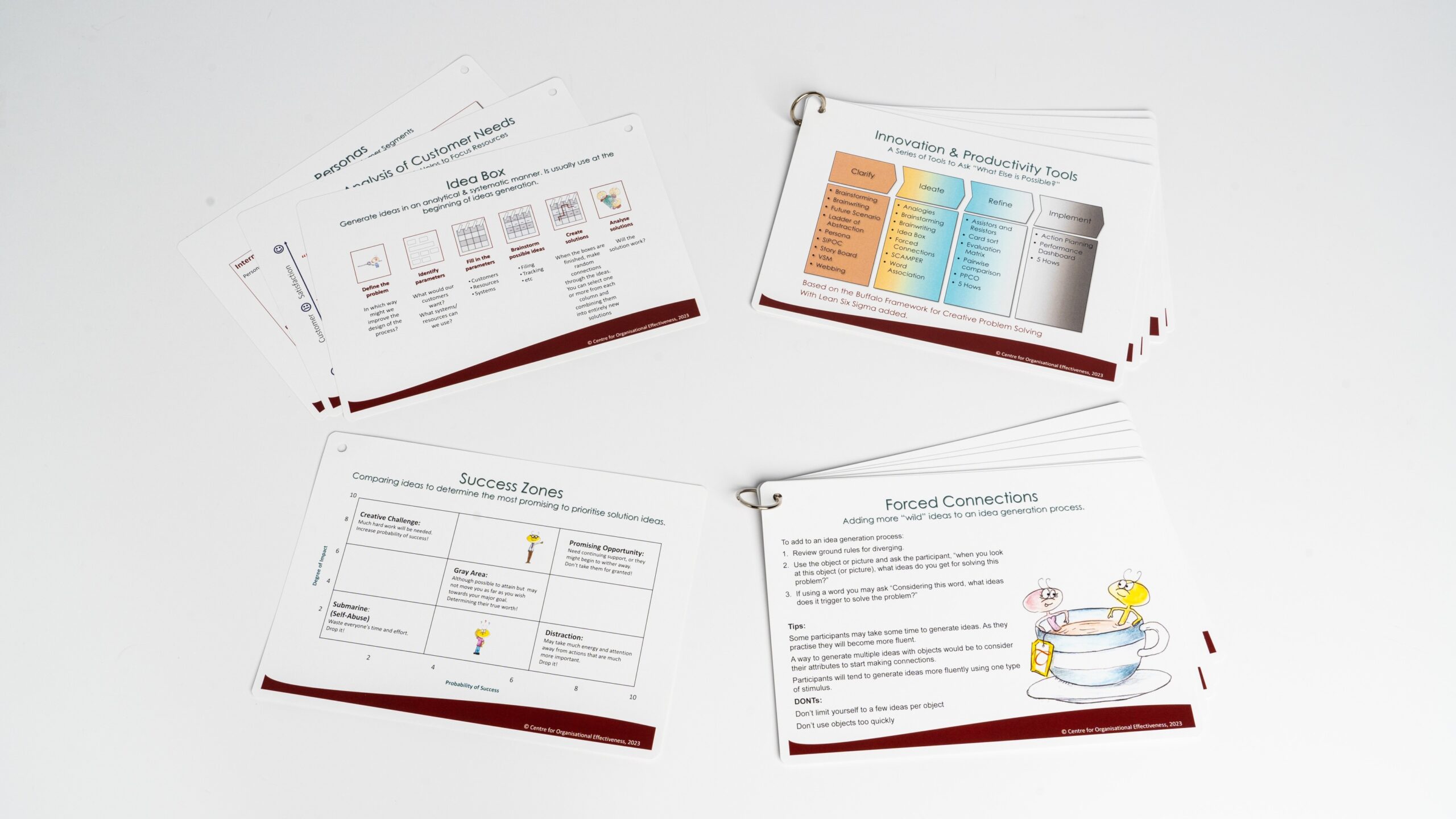

Developing Solutions and Action Plans.

Managing Change. Sustaining the Gains.

Combining Innovation and Lean Six Sigma Will Generate Measurable Results Faster.

Copyright © 2026 by COE Pte Ltd. All Rights Reserved.