19 Nov 2025

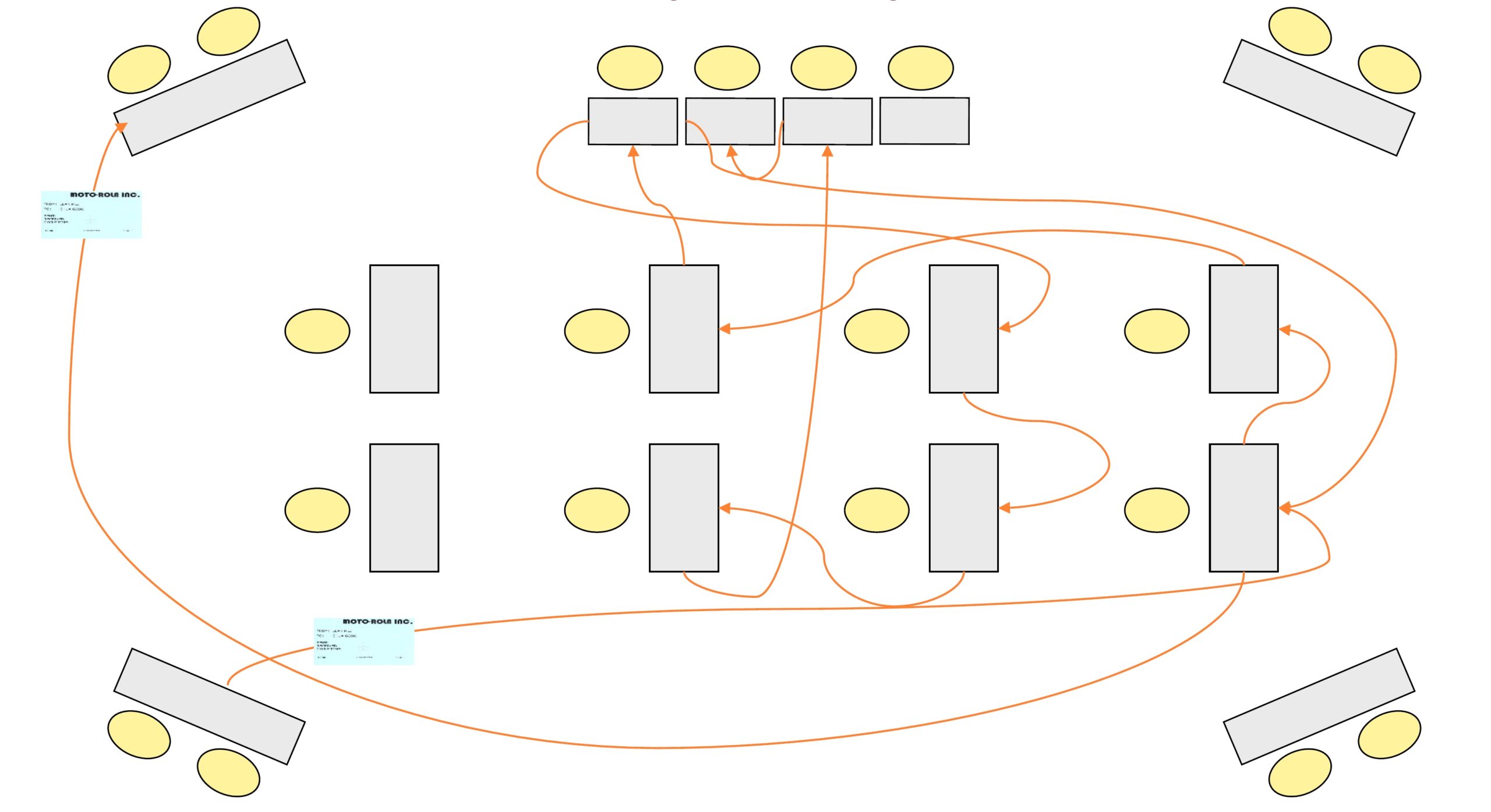

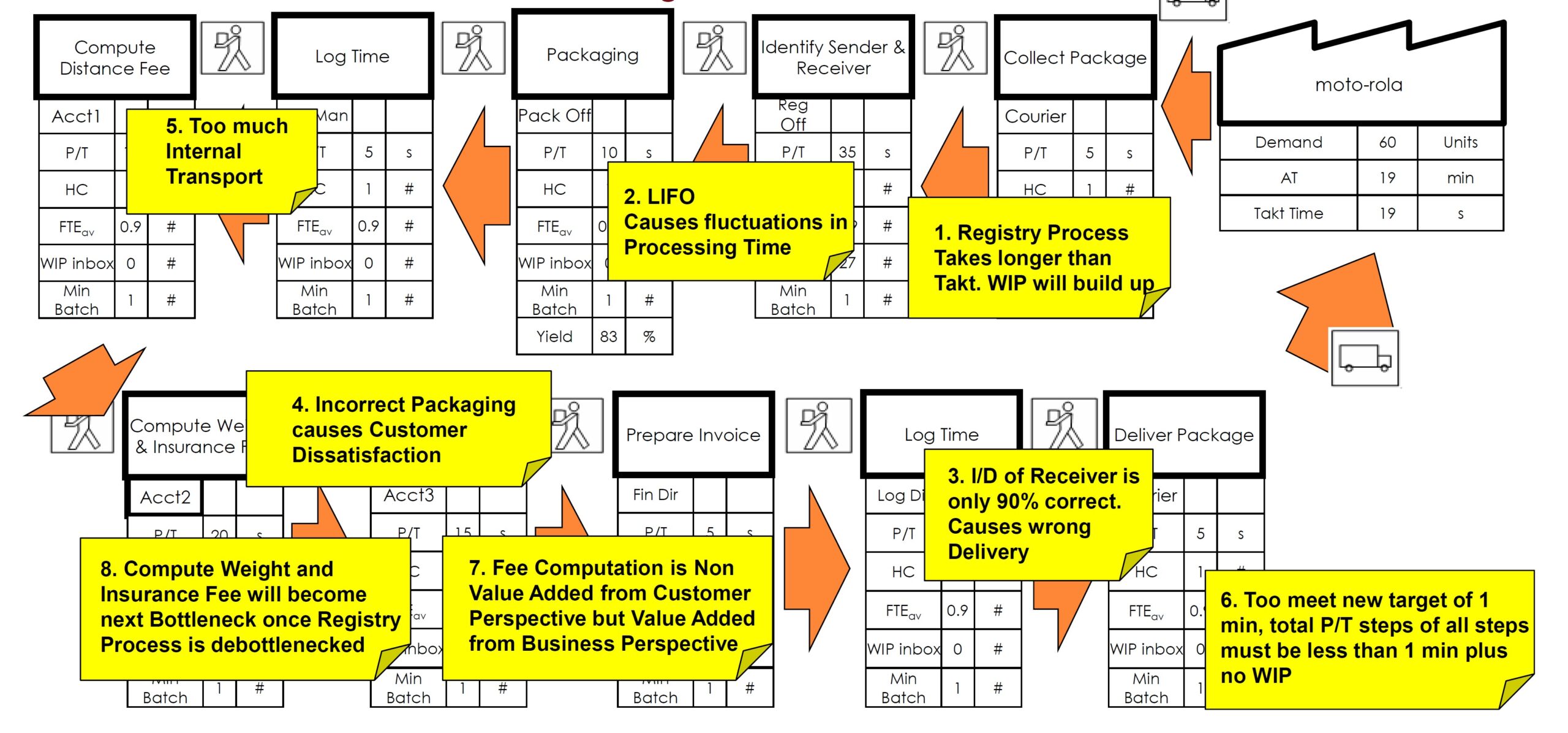

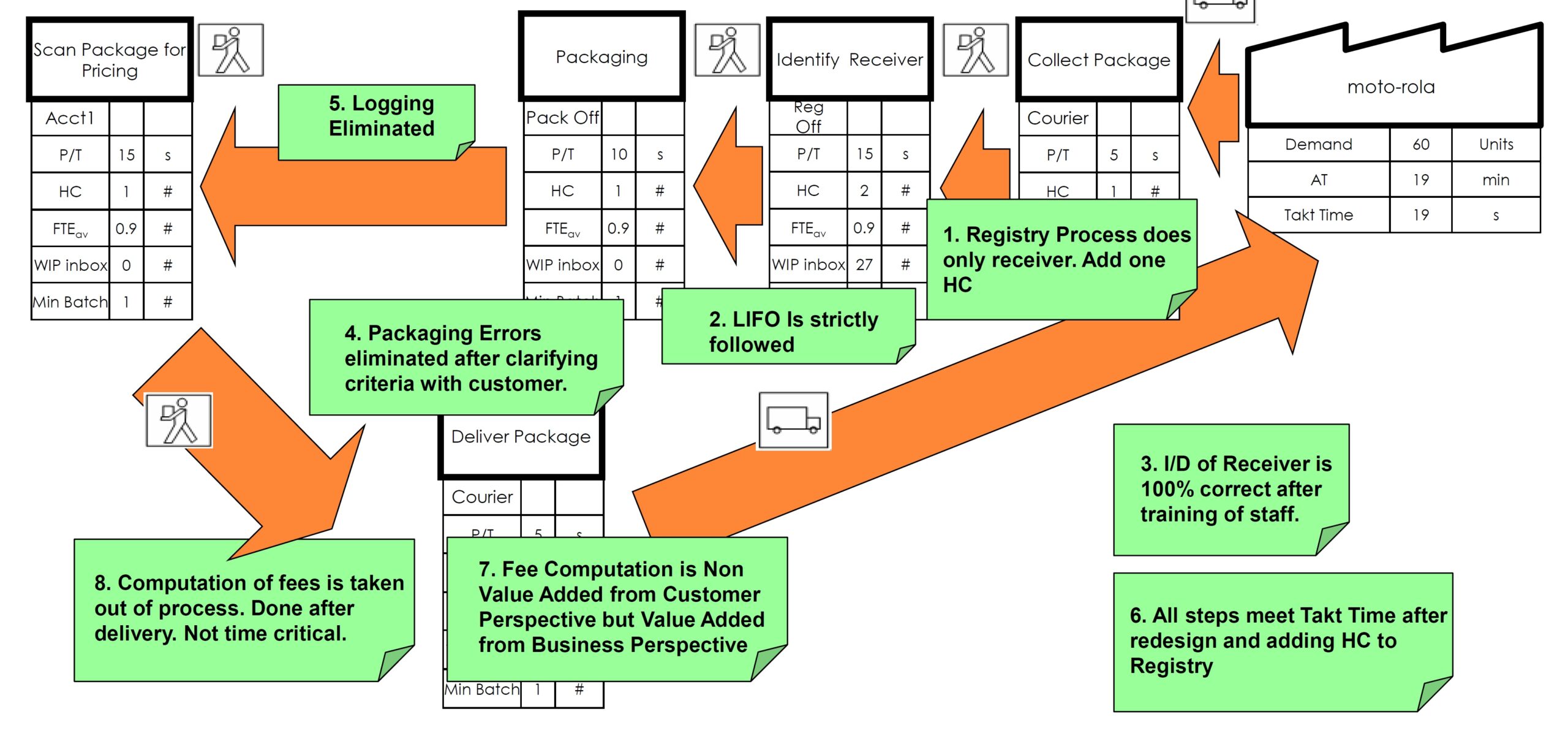

In summary, this map helps identifying waste in multiple forms, summarised in TIMWOODS.

Copyright © 2026 by COE Pte Ltd. All Rights Reserved.