- +65 61000 263

- Contact@COE-Partners.com

- Newsletter

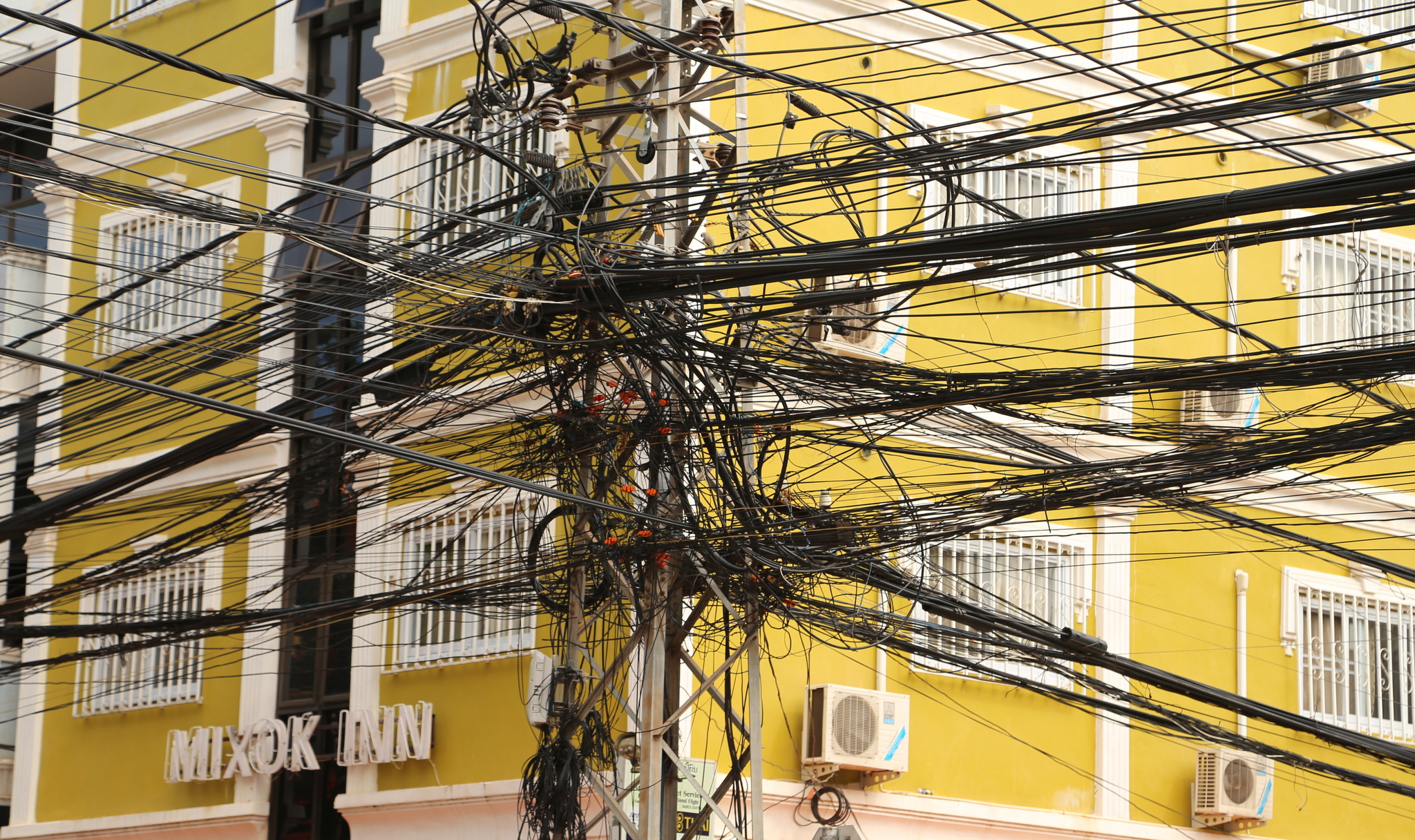

First of all, Lean Six Sigma is a world-wide applied, proven approach for process improvement that consists of tools from two very different methodologies, Lean and Six Sigma.

Firstly, Lean has been developed over decades by Toyota and contains a variety of tools tailored to reduce waste in processes.

Secondly, Six Sigma is a result of Motorola’s successful fight of production problems, resulting in customer dissatisfaction in their TV plants in the 80th and focusses on reduction of the omnipresent variation in processes.

Over more than 30 years, Lean Six Sigma has been contributing to saving billions in dollars of costs as well as to generating additional revenue and income in a variety of organisations in nearly all branches. Because of that, these organisations have been able to improve customer satisfaction and build stronger customer relationships as they turn around their processes in all stages of value creation. At the same time, they have been developing the next generation of leaders for their organisation whilst challenging them with problems to solve, to the benefit of the organisation. Not surprisingly, even government ministries and agencies have been able to use this approach to increase customer satisfaction and process efficiency.

In addition, a LSS initiative often leads to contributing to strategic objectives. For example, when Jack Welch led the implementation of Six Sigma in General Electric in the 90th, he intended and successfully implemented cultural change for General Electric (See Lean Six Sigma Deployment Q&A).

Situation before | Situation after |

| Sporadic use of tools and methodologies for quality improvement. | Proven approaches and tools for quality improvement are used in a disciplined and consistent manner. |

| Goods are shipped to customers and quality problems are fixed thereafter (“Ship and Fix” mentality). | Goods are shipped defect free in accordance to customer requirements. |

| Costs of quality problems are unknown or ignored. | Costs of quality problems are determined thoroughly and communicated to process stakeholders. |

| Values, mind-set and behaviour are driven by functions. | Values, mind-set and behaviours are process driven. |

| Business decisions are often based on gut feeling. | Business decisions are based on collection and analysis of objective data. |

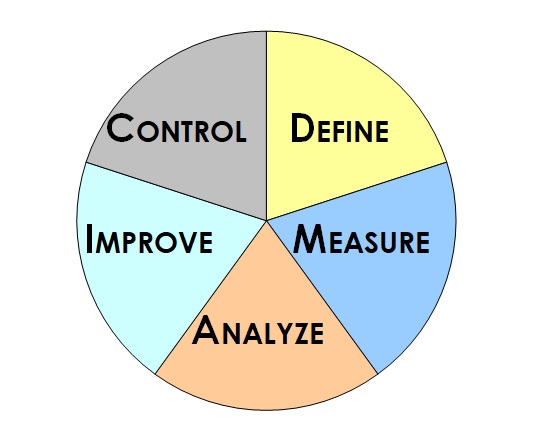

The LSS Methodology consists of five phases and a list of tasks that need to be done in order to complete each of these phases. The phases are:

The LSS Methodology became popular all over the world in all industries to boost productivity, close performance gaps and develop talent. Consequently, our LSS Methodology helps build capabilities in this important methodology (see Why should I become a Black Belt).

Most noteworthy, one of the strengths of LSS is its powerful data analytics toolbox, because data analytics can be helpful in many situations.

Finally, our consulting team brings with them experience in implementing medium and large scale Lean Six Sigma programmes as well as in strategy, organisation and people development and management projects.

Copyright © 2026 by COE Pte Ltd. All Rights Reserved.