- +65 61000 263

- Contact@COE-Partners.com

- Newsletter

Lean Six Sigma IMPROVE Phase

Lean Six Sigma IMPROVE Phase

In the Lean Six Sigma IMPROVE phase, solutions for vital few root causes will be generated, tested and implemented. For these solutions, the effectiveness will be shown to ensure that process changes and sometimes necessary investments yield the intended results.

The principal task of the Lean Six Sigma IMPROVE phase is the generation of solutions for vital few root causes.

The following list of tasks may not be needed for all Lean Six Sigma projects, on the one hand. On the other hand, some projects may even require additional tasks to be completed. The list of tasks required depends on the problem that needs to be solved and the data that needs to be handled.

1. Developing Solutions

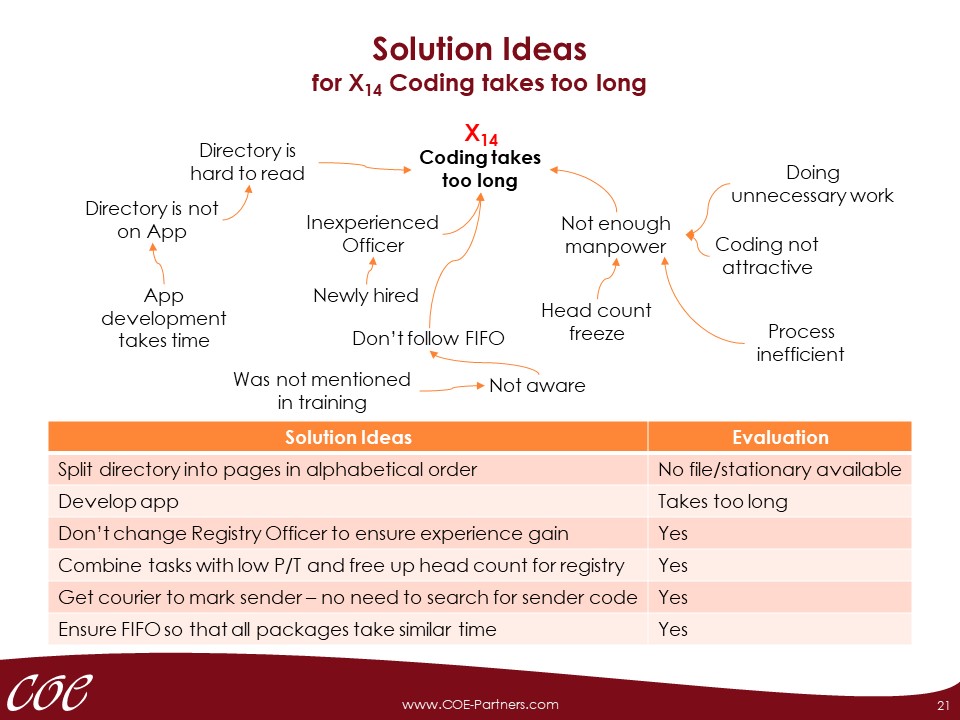

After the critical causes for process problems have been identified and validated, and the drivers have been identified, the design of solutions can begin. While in technical processes the solutions can often be derived from the analysis results, the link between the cause and solution in the service area is often less direct. Therefore, it is advisable to involve techniques to support the solution.

The aim of this step is to generate ideas for solutions, from that develop solutions and evaluate these according to criteria to be defined.

Developing solution ideas is often complicated and requires support techniques. From the variety of available creativity techniques, the following are particularly suitable:

- Brainstorming

- Analogies

- Pictures as idea triggers

The effectiveness of these creativity techniques depends heavily on the Moderator’s experience. As a rule, the application of two of these techniques is sufficient. Brainstorming is often started in order to take up the obvious solutions, the low-hanging fruits, before using a higher-quality technique to generate higher-quality out-of-the-box solutions.

If several solutions are available that can be introduced as alternatives, they must be weighed against each other by using evaluation criteria and the most advantageous ones selected.

Even if several non-competitive solutions are available, an assessment is made. The Evaluation criteria are usually:

- Cost of the solution and its implementation

- Degree of the problem

- Simplicity of the implementation

- Impact on customers

- Impact on employees

Further evaluation criteria can be obtained from the project charter or developed in a conversation with the project sponsor.

The evaluation criteria can be applied with the help of an assessment matrix to the solutions. It is also possible to add weight to the assessment criteria. For instance, “influence on customers” should have a higher weight than “influence on employees”.

This step provides the following results:

- Ideas for solutions,

- Evaluation criteria for solutions and

- Selected solutions and their evaluation results.

2. Analyse Risk and Implement Solutions

After developing solutions and before implementing them, a risk assessment has to be performed.

Similar to technical processes, process changes in service processes can unintentionally increase the risk to the organisation, to customers, employees or the environment. It is therefore useful to make a risk assessment.

From variety of methods for risk analysis, the Failure-Mode-and-Effects-Analysis (FMEA), which has been tried and tested in many companies in all sectors, is used here. FMEA is a tool that helps evaluate the severity, the occurrence and preventability of potential errors, and determines a risk priority number (RPN) from which the overall risk can be assessed.

A pilot test is not only used for risk analysis, but also helps to optimise solutions, verify process results and prepare for the implementation (Figure 2). In addition, a successful pilot test is the best argument to convince process participants and management of the effectiveness of the solution. Successful pilot tests are powerful aids in change management.The implementation of process changes is to be carefully planned and monitored as an important part of the project. Planning should include the following activities:

- Plan activities,

- Estimate the resources required,

- Create or update process descriptions,

- Inform and train the process participants,

- Ensure the necessary support,

- Set milestones with corresponding control points,

- Plan for remedial action in case of problems.

This step provides the following results:

- Risk priority for critical solutions,

- Pilot tests plan and results and

- Implementation plan for the selected solutions.

Conclusion – Lean Six Sigma IMPROVE Phase

After the Lean Six Sigma IMPROVE phase has been completed by undergoing the above mentioned tasks, the Lean Six Sigma phase CONTROL can be started.

This Lean Six Sigma IMPROVE phase has the following deliverables:

- A list of all generated solution ideas with an indication of selection criteria,

- A list of selected solution ideas that have been processed into qualified solutions for improvements,

- A risk register and mitigation measures for solutions and

- An implementation plan for solutions.